Advanced autonomous logistics at scale

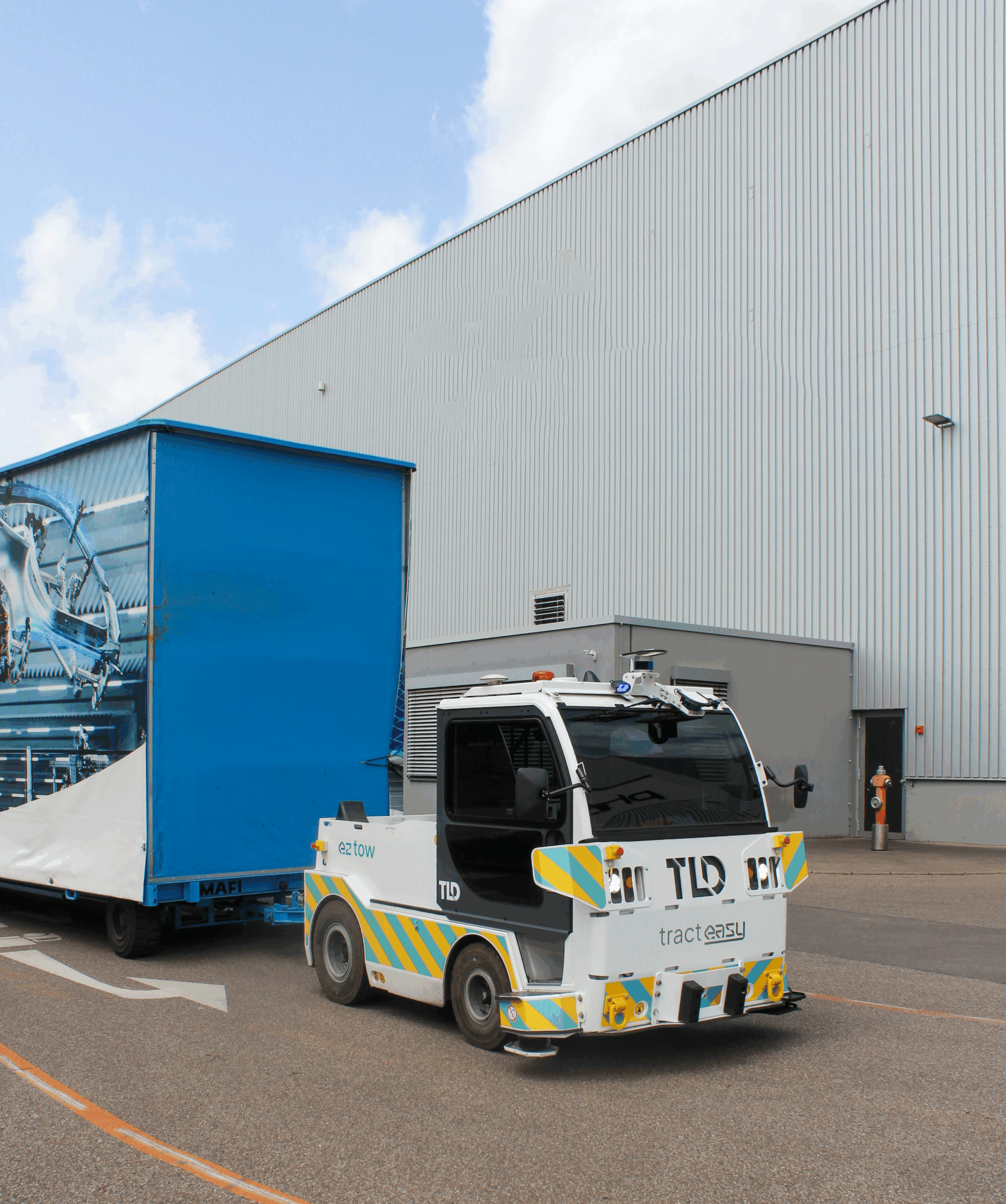

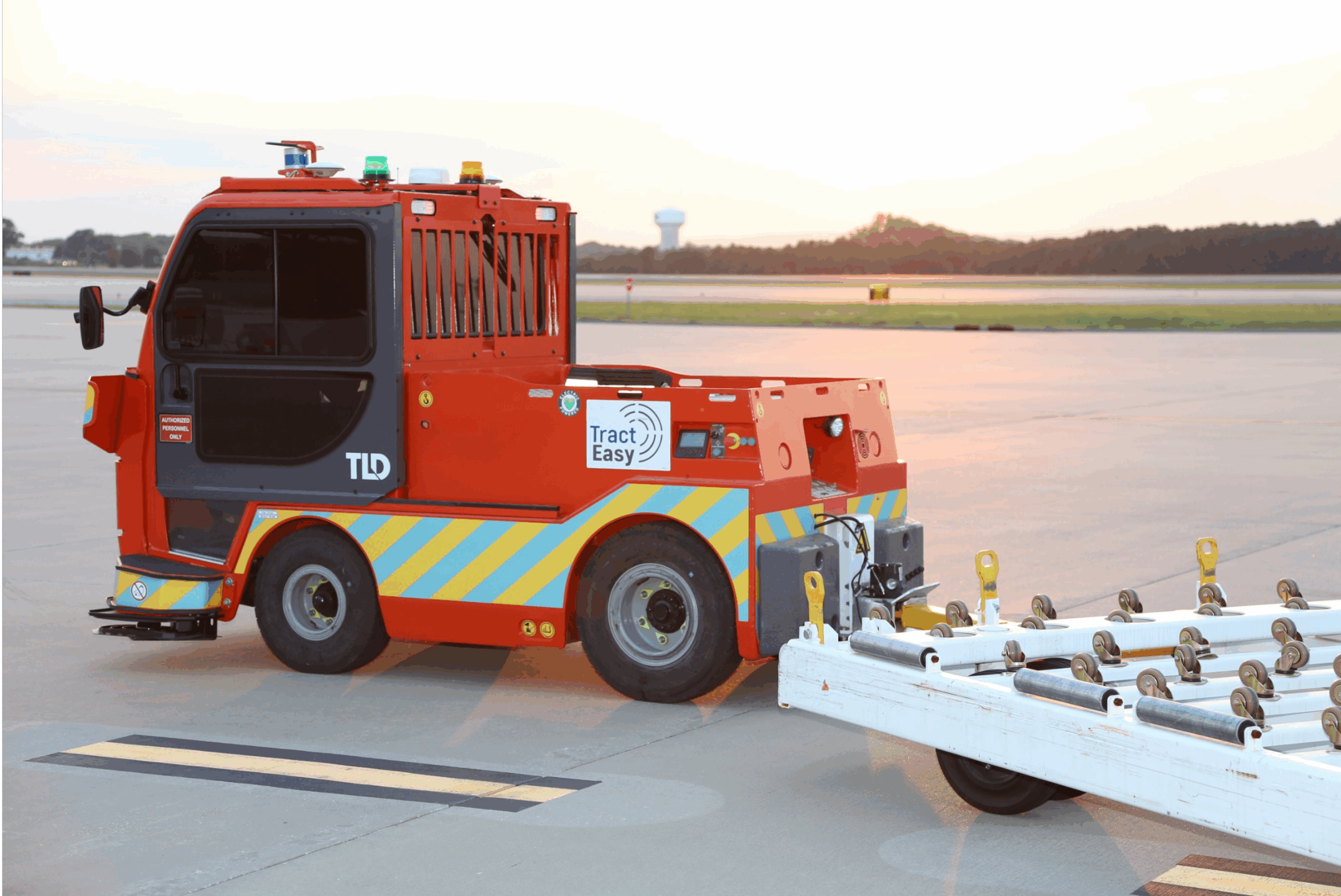

The newly deployed EZTow vehicles, capable of towing 14-ton and 20-ton payloads, now operate on the manufacturer’s largest and most demanding logistics route. The system covers nine production stations over an extensive mixed-traffic circuit that crosses both indoor and outdoor environments. Each vehicle and trailer spans up to 20 meters in length, transporting diverse car body parts between unloading and production points while navigating alongside forklifts and manually driven trucks.

This implementation represents TractEasy’s most sophisticated configuration to date, handling material flows with high volume variability — from compact, heavy containers to bulkier solid-load items — and managing a high number of drop-off points for enhanced flexibility.

Streamlining operations and cutting costs

A key driver for the deployment was the manufacturer’s aim to automate its internal logistics and reduce reliance on third-party service providers. It has also mitigated risks by automating this complicated route including eliminating the potential damage human drivers can make and reducing the testing and training required to ensure drivers can manage this complexity. With EZTow now fully integrated into production operations, the company has successfully eliminated external transport services, achieving significant cost savings and gaining greater control over internal material flow.

“The project’s decisive factors included TractEasy’s ability to meet lead time expectations and infrastructure requirements, as well as the suitability of its vehicles for our specific logistics challenges,” said a representative from the manufacturer’s logistics team.

The solution delivers a highly efficient, adaptable transport flow and is expected to generate a full return on investment within two years.